California is a national leader in pushing renewable energy, lower greenhouse gas emissions and energy efficiency. State manufacturers have contributed to the effort by installing cost-effective technologies and instituting lean manufacturing processes to reduce their demand for electricity, natural gas and transportation fuels.

No other state’s manufacturers have done as much. But with more climate and energy policies being proposed every day, it’s time to take stock of where we are and where we are headed.

If California wants to be a model for others to follow, energy supplies must be both affordable and reliable to support a massive state economy that includes manufacturing and exporting products.

Successful California manufacturers — who employ 1.3 million workers at an average $74,000 salary – depend on priced and reliable energy to operate in this state. They need to stay competitive with manufacturers around the country and the world.

A group including CMTA, the Little Hoover Institute, the California Small Business Association, the California Business Roundtable, and others gathered to discuss the uncertain costs of California’s programs on everyone who pays for electricity, powers a vehicle, or purchases a product in the state.

“There is not a single, credible source of analysis and data that can inform companies and policymakers regarding the cumulative costs of California’s recent energy-related policies,” said Patrick Mealoy of the Navigant Consulting group. Navigant had examined key cost drivers of three prominent California-only energy programs — the 33 percent renewable power requirement, the carbon cap and trade auction, and the low carbon fuel standard.

Navigant’s analysis showed that the industrial community alone has dropped 17 percent of its electricity demand over the last two decades. At the same time, the residential and commercial class grew their demand by about 30 percent. In part, this means that industry is already lean and spent lots of money retrofitting facilities and finding efficiencies so they could compete with the rest of the country. Any new efficiencies could be expensive and either raise the cost of goods or cause the loss of jobs in the California economy.

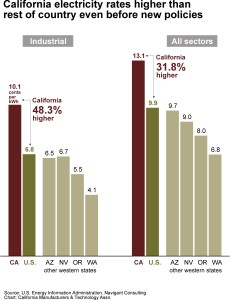

This month, electricity ratepayers, including manufacturers, will see their first big rate increase due partly from the 33 percent renewable power requirement. On average it will be a two-digit percentage hike for ratepayers in the Southern California Edison territory. Industrial electricity rates are already approximately 50 percent higher than the nation. Estimates are far higher than cost of living increases into the future.

Job loss and high energy prices will be unintended consequences of our complex and overlapping clean energy goals. To avoid this outcome, lawmakers should require robust cost-benefit analysis to show how regulations can be reformed to achieve reasonable goals at the lowest possible costs.

The Little Hoover Commission might have said it best at the event, “what California really needs is a ‘timeout’ on new energy mandates.” A timeout so we fully understand what we are getting into can only help make California’s exclusivity a trailblazing success for us and others.

Most of the participants at the event were part of the simultaneous launch of the Californians for Affordable & Reliable Energy coalition (CARE ) – a growing group of companies and trade associations to raise awareness about California’s escalating energy costs. Organizations or companies are welcome to join the coalition here.